The RS AsphaltPlus pavement has born at a time when raw materials become scarce and society demands products that are environmentally friendly. In response, the challenge has always been to create a 100 % recyclable pavement with a longer life than traditional ones and zero waste generations in the manufacturing process. All waste generated in this process is recycled back and incorporated into the pavement itself.

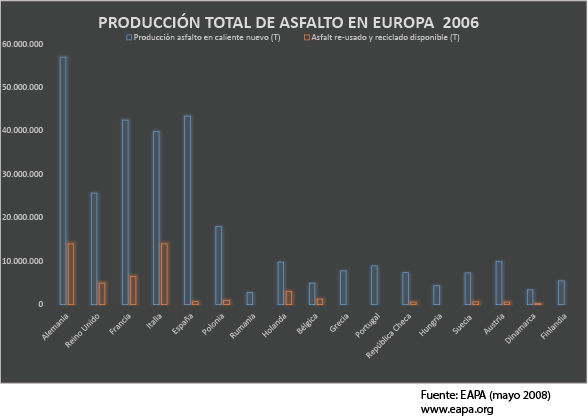

Once we have the challenge of designing a pavement done, we thought it was not enough and we seek to create the pavement from 100% recycled material. Through international partnerships, and by recycling asphalt machinery RS GreenAsphalt VEB, in late 2013 we were able to create the same pavement but with 100% recycled materials. We realized the problems posed by the large amount of asphalt strip still being suitable for use or which accumulates in asphalt plants waiting to enter in a very complicated recycling process. How we see in the conclusions of the study conducted by the "European Asphalt Pavement Association" on 2006, the vast majority of European countries stand out badly in the use of recycled asphalt. Specifically in Spain, the use of recycled asphalt is almost anecdotal even being the second largest producer of bituminous hot mix.

With this new solution, RS Tecnologia gets finally a pavement 100 % recycled and recyclable, very environmentally friendly and very inferior to other flooring cost. The recycled asphalt, meanwhile, provides the same guarantees as the new one.

Different academical studies demonstrate the asphalt ecological nature and its aplication out of the rouds.

Planning strategies for promoting environmentally suitable pedestrian pavements in cities

Planning strategies for promoting environmentally suitable pedestrian pavements in cities

Life cycle assessment of granite application in sidewalks

Life cycle assessment of granite application in sidewalks

Environmental optimization of concrete sidewalks in urban areas

Environmental optimization of concrete sidewalks in urban areas

We would to thank Joan-Manuel F. Mendoza, Jordi Oliver-Solà, Xavier Gabarrell, Joan Rieradevall and Alejandro Sosa of the Universitat Autònoma de Barcelona.